Kemiske procespumper er væsentlige komponenter i industrier, hvor den præcise håndtering af væsker og kemikalier er kritisk. De er konstrueret til at transportere aggressive, ætsende, tyktflydende og højtemperat...

Læs mereSepex tilbehør Producenter

Kontakt os

information to be updated

Key Components of SEEPEX Screw Pumps

Rotor

Function: The rotor is a rotating screw that moves fluid through the pump. In a SEEPEX screw pump, the rotor's helical design creates a continuous, sealed cavity that transports the fluid from the inlet to the outlet. The rotor is critical for the pump’s ability to handle various fluid types with minimal pulsation and shear.

Stator

Function: The stator is a stationary component that surrounds the rotor. It works in tandem with the rotor to form and maintain the sealed cavities through which the fluid flows. The stator's material and design are crucial for ensuring efficient fluid handling and minimizing leakage.

Bearing Housing

Function: The bearing housing supports the rotor's shaft and bearings, ensuring smooth rotation and reducing mechanical wear. It plays a key role in maintaining alignment and minimizing vibration.

Shaft

Function: The shaft connects the rotor to the driving mechanism, such as a motor. It transmits rotational motion from the drive to the rotor, facilitating the movement of fluid through the pump.

Seal

Function: Seals prevent fluid from leaking out of the pump and protect the internal components from contaminants. They are crucial for maintaining pump efficiency and preventing operational issues.

End Plates

Function: End plates seal the ends of the pump casing and support the rotor bearings. They ensure the integrity of the pump’s internal structure and assist in maintaining proper alignment.

Common Replacement Parts for SEEPEX Screw Pumps

Regular maintenance and timely replacement of worn or damaged parts are essential for the efficient operation of SEEPEX screw pumps. Common replacement parts include:

Rotor and Stator Assemblies

Description: These are often replaced as a set because they work together to form the pumping mechanism. Wear and tear on these components can affect pump performance.

Signs of Replacement: Reduced pump efficiency, increased vibration, and inconsistent fluid flow are indicators that the rotor or stator may need replacement.

Bearings

Description: Bearings support the rotor shaft and are critical for smooth operation. They are subject to wear and may require replacement if they become noisy or cause excessive vibration.

Signs of Replacement: Grinding noises, increased vibration, or excessive heat are signs that the bearings may need to be replaced.

Seals

Description: Seals prevent leaks and protect the pump’s internal components. They may need replacement if they become worn or damaged.

Signs of Replacement: Leaks around the pump, loss of pressure, or contamination of the fluid are common signs that seals should be checked or replaced.

Shaft

Description: The shaft transmits rotational motion from the drive to the rotor. If the shaft becomes damaged or misaligned, it may need to be replaced.

Signs of Replacement: Vibration, noise, or difficulty in rotating the pump are indicators that the shaft may need attention.

End Plates

Description: End plates seal and support the pump casing. They may require replacement if they become damaged or if there are issues with alignment.

Signs of Replacement: Leaks, misalignment, or visible damage to the plates are signs that they may need replacement.

Conclusion

Understanding the components and common replacement parts of SEEPEX screw pumps is essential for maintaining satisfactory performance and extending the lifespan of the equipment. Regular inspection and timely replacement of worn or damaged parts help ensure the pump operates efficiently and reliably. By paying attention to these key components and their signs of wear, operators can effectively manage their SEEPEX screw pumps and avoid unexpected downtime.

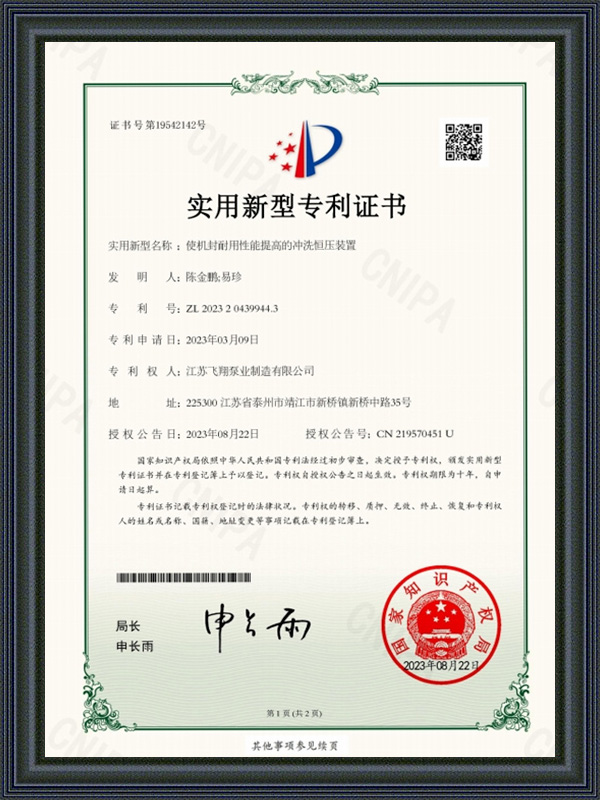

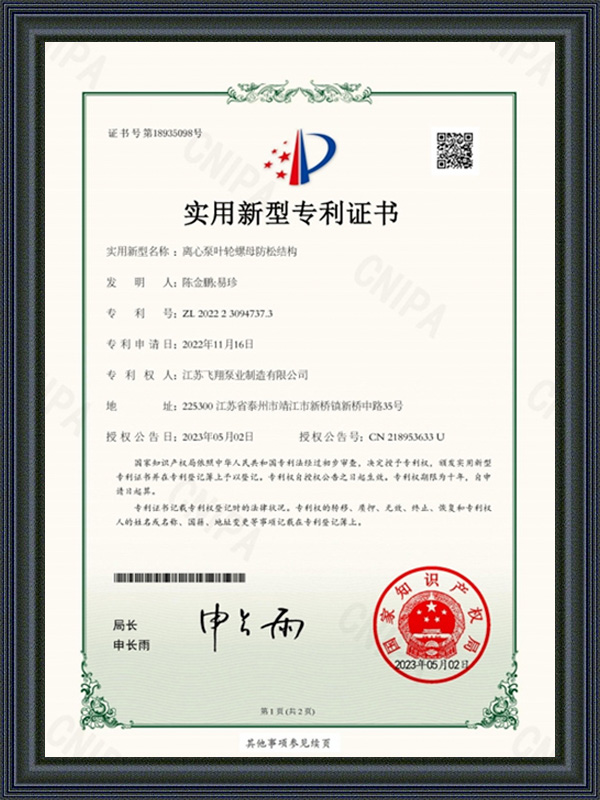

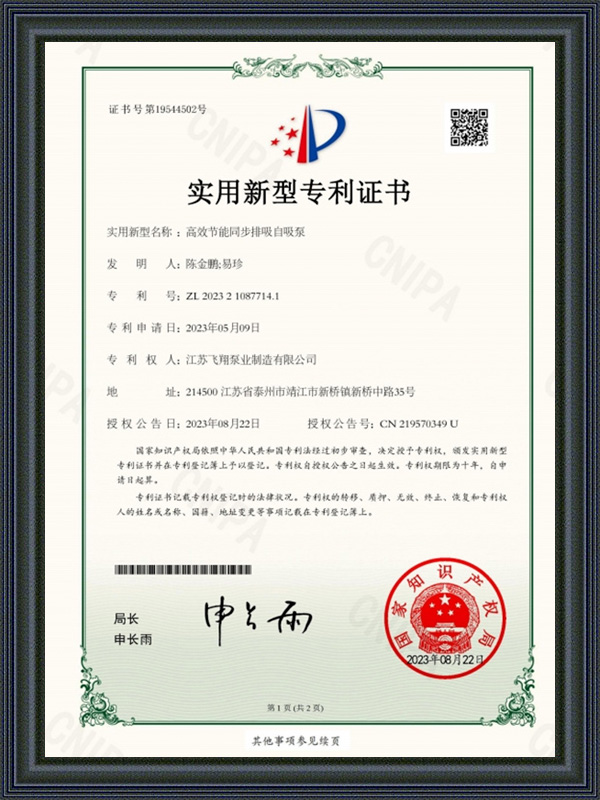

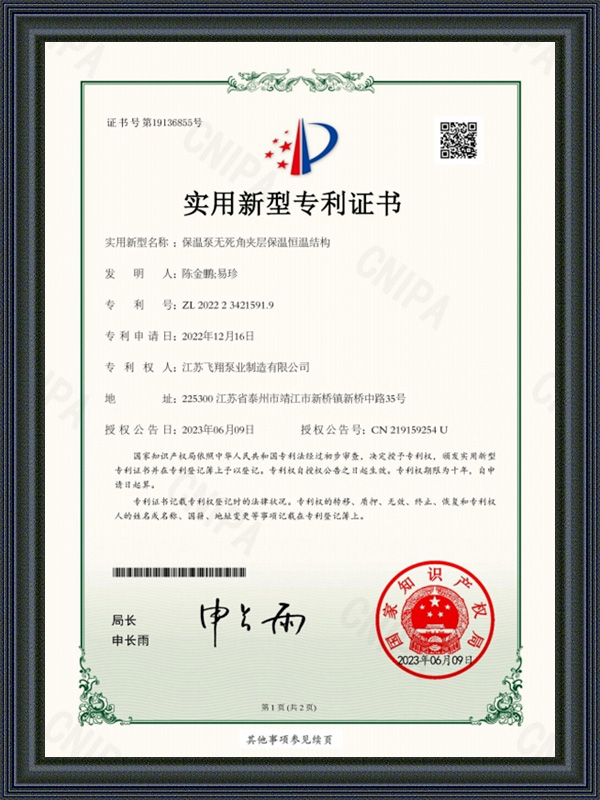

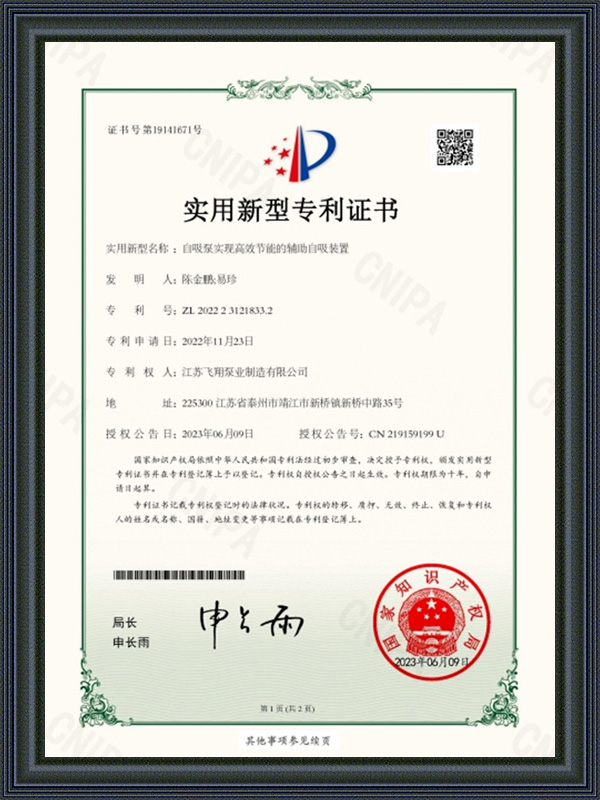

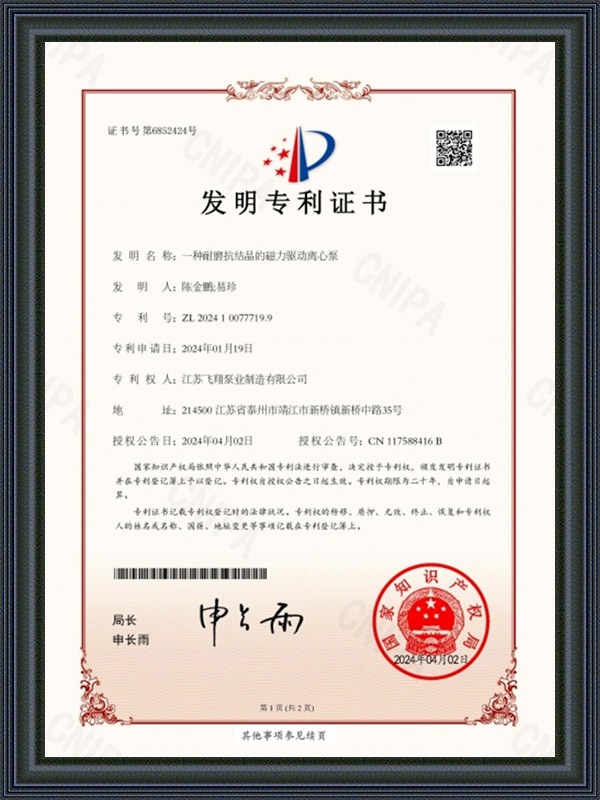

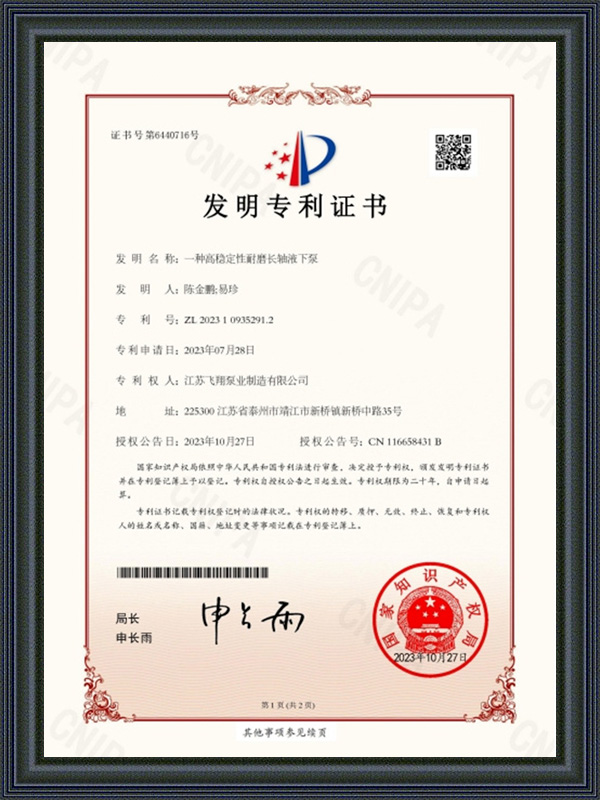

Jiangsu Feixiang Pump Manufacturing Co., Ltd. blev grundlagt i 1980'erne. I 2001 blev Jiangsu Feixiang Pump Manufacturing Co., Ltd. oprettet af selskabsloven. Virksomheden integrerer videnskabelig forskning, design, produktion, drift og service, og dets virksomheds natur er et begrænset ansvar. Det er nu en medlemsfabrik fra Sound Material Resources Network of Sinopec Group Corporation, en tilfredsstillende netværksmedlem i raffinering af forsyninger og tilbehør fra China National Petroleum Corporation, en nøglevirksomhed i den højteknologiske intensive zone i Jiangsu-provinsen, en virksomhed, der overholder kontrakter og holder løfter og Kinas generelle mekaniske pumpeindustri. Medlem, selvbetjent import og eksportvirksomhed i Folkerepublikken Kina.

Virksomheden har fem workshops, herunder casting, bearbejdning, fluoroplastisk pumpepresning, slutmontering og malingemballage og fem funktionelle afdelinger på et værelse, herunder salg, teknologi, produktion, kvalitetsinspektion, finans og et omfattende kontor. Det har i øjeblikket 256 ansatte, herunder 5 senioringeniører, 28 ingeniører, 136 teknikere og 66 ledere af forskellige typer. Virksomheden dækker et område på 38.000 m2 og har anlægsaktiver på 18 millioner yuan. Virksomheden har komplet produktionsudstyr, fysisk og kemisk test og testudstyr og har et vandpumpe-testcenter af høj kvalitet (måling af rækkevidde: 0,5-20000m3/h, hoved: 2-2900m). De vigtigste produkter produceres ved hjælp af internationale standarder og avancerede udenlandske standarder.

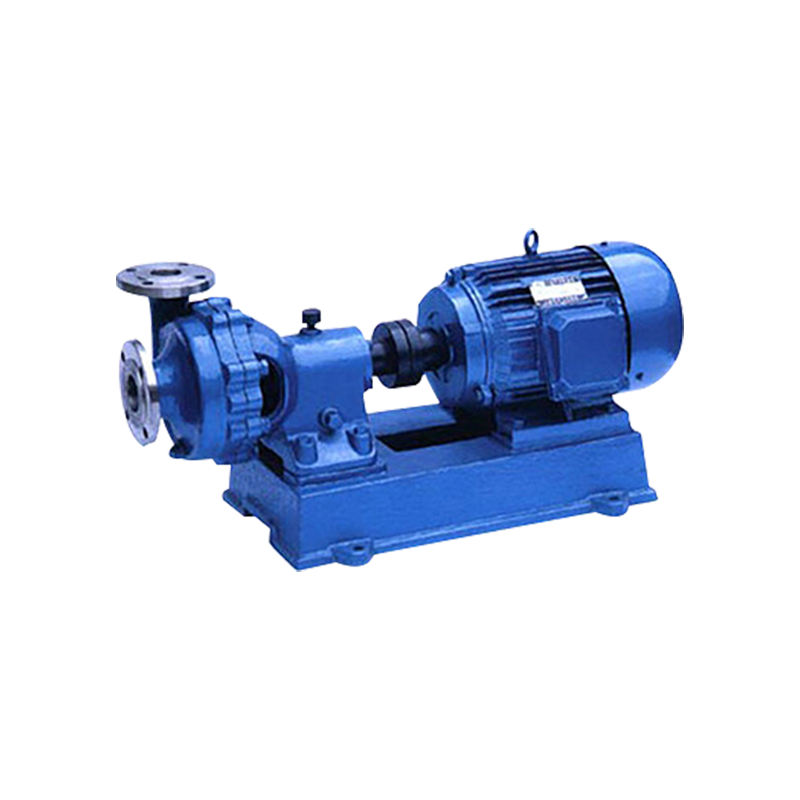

Virksomhedens velrenommerede produkter inkluderer 26 serier og 460 specifikationer og sorter. The main products are FXLB type non-clogging cyclone pump, ZA, CZ type chemical process pump, ZE type high-temperature pump, IJT type titanium nickel chemical pump, FIJ type alkali pump, IH type chemical centrifugal pump, FXP rotary jet pump, DF type multi-stage pump, WFB type sealless self-control self-priming pump, FSB type fluorine alloy Pumpe, FIEC-type fortyndet syrepumpe, FIU-mørtelpumpe, fyltype lang skaft nedsænket pumpe, spp-type kemisk blandet flowpumpe, fjx type tvungen cirkulationspumpe, FCJ, FHJ desulfurization pumpe, JFRB dobbelt sugning smelter urinstofpumpe, JyM membragmmålingspumpe, rotorpumpe, Hzp type slurry pumpe, zxb type selv-priming pumpe, othragm memering pumpe, osv.

Produktets vigtigste materialer er 304, 304L, 316, 316L, CD4MCU, 904L, MO3TI, 20# legering, TA2, TA3 Pure Titanium, TA9 Titanium Palladium Alloy, Hastelloy, F46 Fluoroplast Alloy, Uhmwpe, Steel-linje, korrosions-Resistant og Wear-Resist.

Feixiang -produkter sælger godt over hele landet og er vidt brugt i olie, petrokemisk, kemisk, metallurgi, elektrisk strøm, minedrift, medicin, let industri, mad, bilproduktion, papirfremstilling, miljøbeskyttelse og andre industrier; Blandt dem fortyndede FIU-mørtelpumpe, JFRB dobbelt sugning af urinstofpumpe, ijt type titanium nikkel-kemisk pumpe, FXP-rotarisk jetpumpe og andre produkter, der er anvendt i pakning af titanium-nikkel-kemisk pumpe, FiU-mørkepumpe og andre industrier for at erstatte import af titanium-nikkel, og andre produkter, ikke anvendte cyklonpumpe og Fiect-type, at fortyndes syrepumpe og andre, der ikke-bremede cyklonpumpe og Fiect-type, at fortyndes syren af brugere. Favør.

-

-

Kemiske spildevandspumper er specialdesignede pumper til overførsel af spildevand, der indeholder ætsende kemikalier, suspenderede stoffer og slibende partikler. I modsætning til almindelige spildevandspumper br...

Læs mere -

Kemiske procespumper er kritiske komponenter i industrianlæg, ansvarlige for at transportere ætsende, tyktflydende eller højtemperaturvæsker sikkert og effektivt. De er meget udbredt i kemisk fremstilling, farma...

Læs mere